Micro-nano Systems Laboratory

- KEYWORDS

- MEMS/NEMS

- bio-nanotech

- energy harvester

Micronano Systems for biotechnology, nanotechnology and energy harvesting

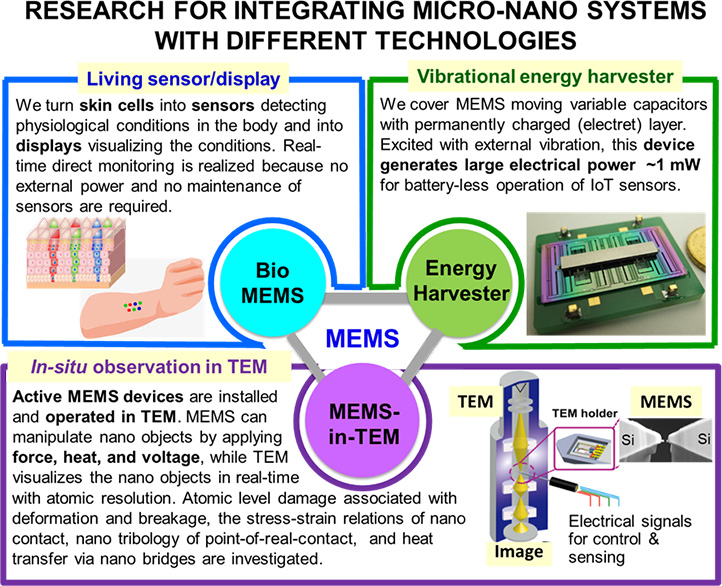

In this laboratory, MEMS (micro electro mechanical system) design, fabrication, and evaluation have been studies over 40 years from the emergence of the technology. Currently, its application to nano and bio technologies as well as vibrational energy harvesters are investigated. Research on nano science and engineering using MEMS devices covers the electro-mechano-thermal characterization of nano contacts in transmission electron microscope (TEM) for in situ atomic level observation of its shape and dimensions. We are proposing a “living device” concept for bio sensing. We have genetically modified skin cells to detect early infection signals and to exhibit fluorescent signal upon detection. MEMS electrostatic energy harvesters can generate as large as 1 mW from environmental vibrations.

Research staff

Ph.D., Professor

Micro-nano Mechatronics, Bio MEMS

Overall topics

Research activities

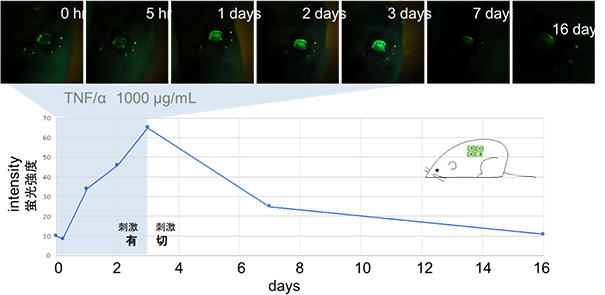

Living Sensor/Display on Skin for Infection Monitoring

Living cells on the skin are used as sensors to detect physiological conditions inside the body, such as early infection signals, and as a display to visualize the conditions. This sensor remains in the same position and size forever, like a mole, and keeps functioning for the lifespan of the living body, allowing lifelong monitoring.

- ・Health conditions can be checked at home (early detection of poor health to be diagnosed at a clinic).

- ・Living devices do not require sensor maintenance or external power, so they continue to operate continuously.

- ・In a mouse model, a clear fluorescent signal is observed for several days after stimulation (see pictures and photos).

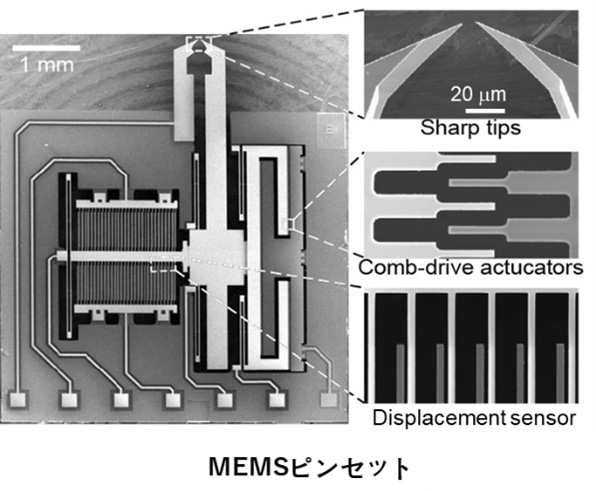

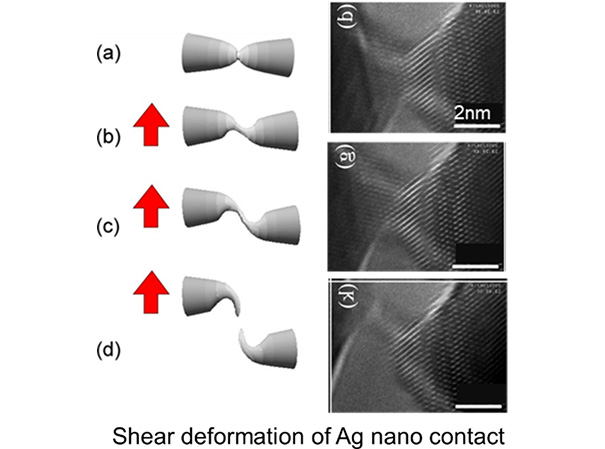

In-situ TEM observation using MEMS-in-TEM setup

Features

- ・Electrical, mechanical, thermal and biochemical properties of a nano object are measured simultaneously during TEM-atomic-level observation

- ・MEMS chips have multiple functionalities such as mechanical stress application, thermal control, and liquid encapsulation.

- ・Monolithic silicon structure and electrostatic actuation enable very stable observation over hours

MEMS vibrational energy harvester

Features

- ・Electrical power as high as 1 mW generated from faint environmental vibration (~0.6 G)

- ・Mass fabrication based on MEMS technology

- ・High conversion efficiency due to strong electret formation in a high-aspect-ratio gap